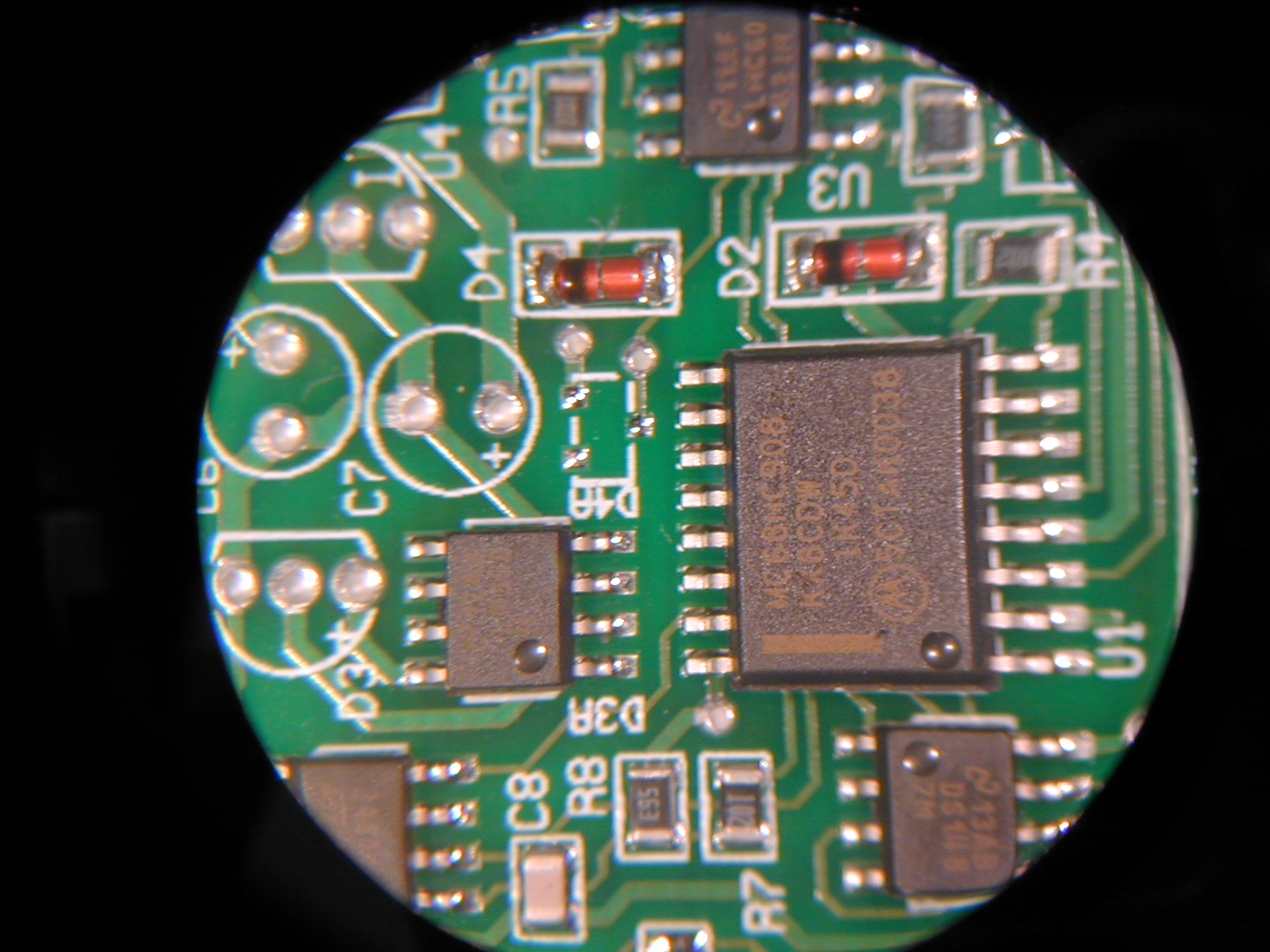

Optical test

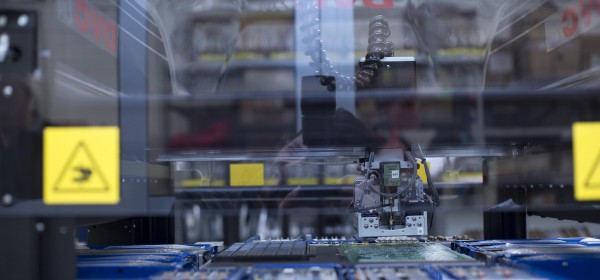

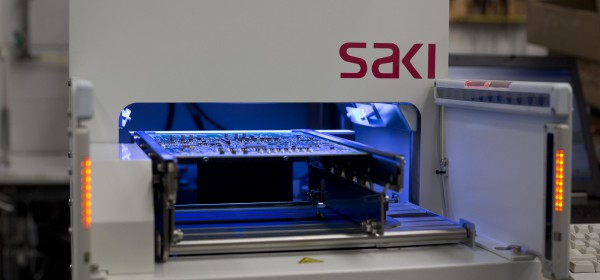

From January 2007, Montel has adopted a high-speed automatic inspection system called SAKI, to supervise SMT and THT boards (where permitted for size and height).

This system, unlike other AOIs, has a linear camera (non-standard) whose main characteristics are:

- Work size 330x250mm.

- Camera width 18 micron

This allows viewing a pixel size images.

Unlike other systems, SAKI captures images in RGB color system, with telecentric lens, while 70% of similar systems analyze in black and white, then transforming a color image.

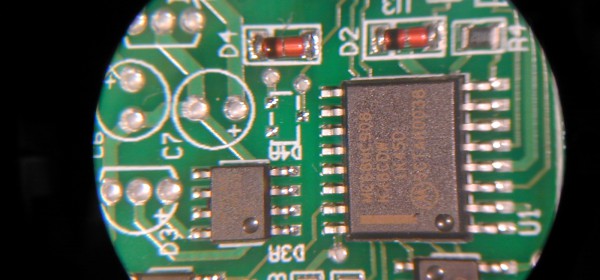

Directly acquiring colours, SAKI obtains a greater resolution and accuracy of the images, with the possibility to control also very small components such as 0201 and fine 0.3 mm pitch.

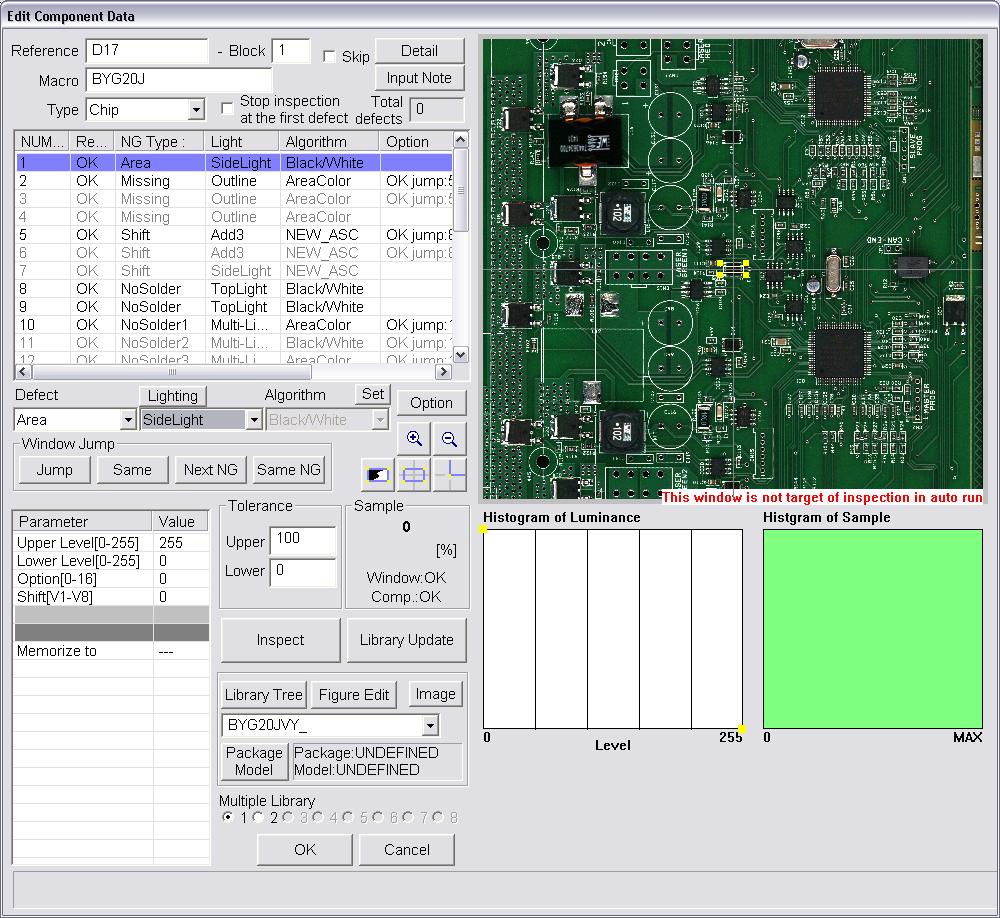

Unlike other similar systems, SAKI has three different types of light useful to analyze the images: TOP, SIDE and LOW. You can select the most suitable light to search any errors.

Moreover, while most desktop systems work in IMAGEMATCHING mode, comparing acquired images with a sample card visually controlled in advance, SAKI processes images using mathematical algorithms that transform the image into numbers allowing comparison with the previously set program.

Thanks to this technology, SAKI gets greater control accuracy, reliability and repeatability.

Obviously, the reliability of the Optical Test also depends on the professionalism and experience gained over time by the supervisor of the verification program.

Since 2007, we have accomplished innumerable programs so we can guarantee a correct performance, also thanks to the reliability of our libraries created during the years.

SAKI automatic inspection system easily identifies:

- Missing components.

- Incorrect value.

- Mismatch.

- Incorrect polarity.

- Raised component.

- Short circuit.

- Fat, thin or missing welding.

- Overturned component.